These bearings are often referred to as sleeve bearings or journal bearings.

Journal bearing vibration sensor.

Journal bearing description most rotor support bearings are either.

Vibration detection on sleeve bearing equipment.

Vibration sensor selection 3.

Lated measurements eddy current probe systems are the best solution for shaft posi tion measurements in sleeve bearing equip ment the selection and speciications of skf s range of eddy current probes is.

There are no rolling elements in a plain bearing and typically the shaft is supported by a film or wedge of oil.

Aside from typical mechanical issues such as misaligned couplings and unbalance the vibration analyst can also detect electrical issues that cause mechanical vibrations.

Since they have significant damping fluid film journal bearings have a strong impact on the vibration characteristics of machinery.

Physical characteristics such as temperature rating size and connector orientation are also considerations.

Machines utilizing sleeve journal bearings they have excellent frequency response with.

This intelligent vibration sensor continuously trends and stores overall vibration temperature and bearing condition in 3 directions.

Lubrication technology goes hand in hand with understanding journal bearings and is integral to bearing design and application.

Centrifugal pumps proximity seismic bearings are better monitored with proximity probes but general pump issues may be better.

Wirelessly access stored data through any smart phone or tablet during routine inspections.

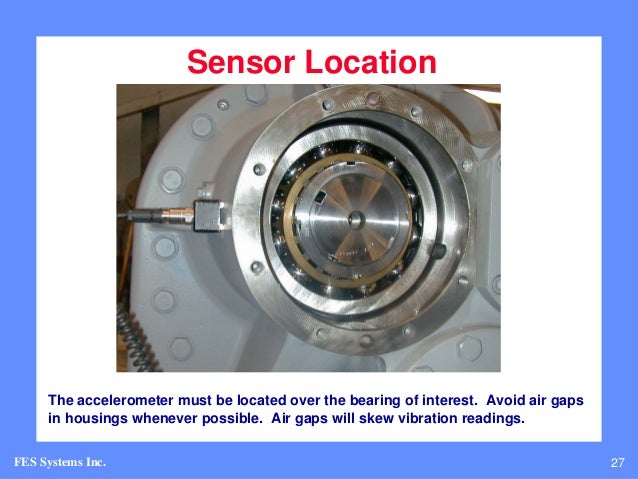

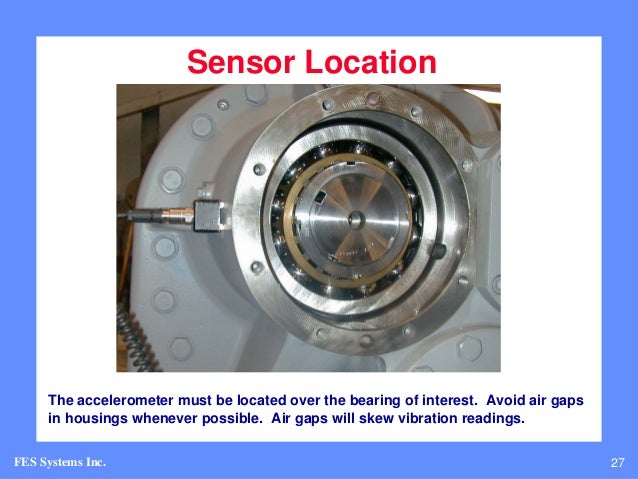

So you d rather focus on the force in vibration rather than the displacement which means you shall use an accelerometer.

Eddy current sensors are non contact devices that measure the position and or change of position of a conductive component.

The last type of vibration sensor we will discuss is an eddy current or capacitive displacement sensor.

Individual sensor cables into a large multi conductor cable typical multi conductor cable plain bearings some fans and motors are equipped with plain bearings.

Based on the mathematical model of a symmetric rotor supported by one rigid journal bearing and one oil film journal bearing muszynska 1 2 mathematically interpreted the dynamic phenomena related to synchronous vibration and self excited vibration.

If your machine has anti friction bearings rolling element bearings the expected vibrations are usually very small in displacement amplitude to be discovered clearly with a proximity probe.

Relying on a pair of orthogonally installed proximity sensors the orbit of the shaft.

Often need to use both sensor types.

These sensors operate with magnetic fields.

The range of vibration sensors offered is wide as a vibration sensor has many different characteristics that may vary including measurement related factors such as frequency response sensitivity and accuracy.